It is a link to move a page.

Glue Machines

Even amount of glue application helps to reduce glue consumption dramatically and to produce stable sheet quality.

Contact bars helps solve flute crushing caliper loss and warping problems.

Specifications

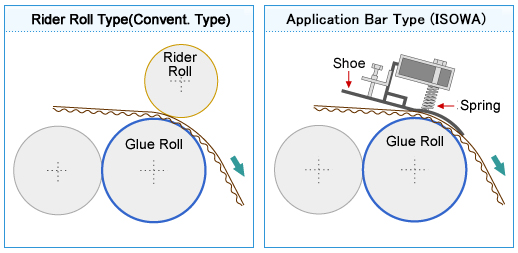

By eliminating the conventional rider roll, the Isowa Glue Machines solved a lot of old problems. We offer three different models to suit your specific production needs.

| Model | Glue Machine GU50 |

Glue Machine GUD6 |

Glue Machine GU10 |

|---|---|---|---|

| Max. Paper Width | 2,000mm | 2,500mm | 2,500mm |

| Max. Production Speed | 300m/min. | 300m/min. | 350m/min. |

| Dia. of Glue Roll | 270mm | 350mm | 320mm |

| Dia. of Doctor Roll | 170mm | 210mm | 210mm |

| Machine Dimension *1 (Length~Width~Height) |

1,312mm ~4,200mm ~2,697mm |

1,767mm ~4,194mm ~2,706mm |

1,540mm ~4,256mm ~2,975mm |

| Number of Installatoins *2 | 262unitsiUp to Dec. 2005j | ||

*1 In case of 2,000mm Max. Paper Width Machine

*2 Including of GUD4AGUD5AGUD6AGUD8AGU50 and GU10

Features

| Unlike the rider roll, the Application Bar only applies a small amount of pressure. No gap controlling is necessary between the glue roll and the Application Bar |  |

Sheet strength is increased, making it less likely for flutes to be crushed. |

|---|---|---|

| Since flute crushing is greatly reduced, only the proper amount of glue is applied to the flute tip, resulting in good, consistent pressure lines. |  |

Sheet warping is reduced. |

| Equipped with independent drive. |  |

The Glue Roll speed is automatically controlled based on web combination. |

| Glue gap control system is standard equipment. |  |

The best glue gap is always selected for the sheet combination and production speed. |

Internal Structure

See the difference between the conventional rider roll concept and the Application Bar concept.

Field Service by Isowa

We are very proud to have service that is as good as our machines. Please click here to find out more about Isowafs field service.

¨Go to Service for details

Corrugators

Corrugator Equipment (Wet End)

Corrugator Equipment (Dry End)